Heavy Hauling: Strategies for Safe and Successful Transportation

Heavy hauling plays a crucial role in the logistics industry, ensuring the transportation of oversized and overweight cargo to various destinations. From construction machinery to

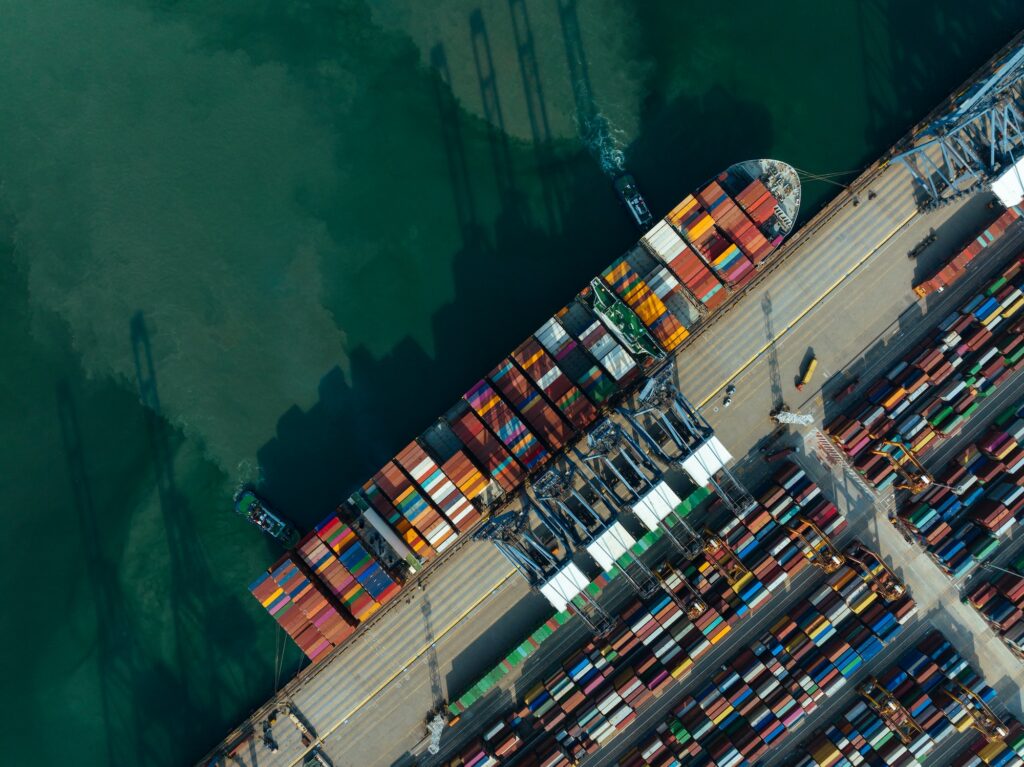

Drayage is a term that refers to moving a container over a short distance. This usually refers to a shipping container it was shipped with on a ship. This means that the container is already loaded with the product. All that the drayage company has to do is pick that container up with a truck and move it to the various other methods of transport. These other methods of transport can be another truck, rail, ship, or other means of transportation. It can also be moved to a warehouse where the container is opened and then broken down into various shipments.

While the Drayage is a very small part of the logistics of that container, it is a very important part. It helps move the containers freely at the port. This keeps the ports from getting too congested. However, the equipment used in the drayage process is quite simple. It is usually a semi truck capable of picking up the shipping containers.

The containers that drayage shippers are moving are usually the size of what you would see on the back of a semi. They can be dry or refrigerated.

The logistics of transporting, storing, and distributing chilled and frozen goods are collectively called the “cold chain.” The cold chain must be maintained at all times.

Refrigerated shipping containers are a part of the cold chain. During the shipping process, these containers, which are also known as reefer containers, are intended to keep perishable goods at a cool temperature. Items that are required to be transported at a constant temperature can be transported using reefer containers. It is common practice to ship perishable goods such as cut flowers, produce, pharmaceuticals, and more in containers that require refrigeration.

Refrigerated containers are built with the ability to function on their own. This ensures that they will maintain their temperature throughout the journey. This is true regardless of whether they are transported by ship, truck, or rail.

The insulation of reefer containers consists of nearly two thousand pounds of foam. Furthermore, these containers also have their own cooling mechanisms. The refrigerator you have in your kitchen functions similarly to how reefer containers do, but on a much larger scale. The compressor, the condenser, and the evaporator are the three main components that make the reefer trailer work to keep the container at a cool temperature.

The idea of drayage is not brand new. The most up-to-date trucks and shipping containers are utilized in today’s methods of drayage. However, were you aware that drayage dates back to the time before the 18th century? According to historians, drayage dates back to a time before the industrial revolution.

In fact, the word “dray” is where the term “drayage” originates from. A dray was a type of cart that was pulled by horses. Dray horses were responsible for transporting very heavy loads of freight. Due to the substantial weight of the cargo, the horses were only capable of covering short distances. Nearby ocean ports, canal terminals, and railroad terminals were all areas of operation for the horses and carts. Before trucks came along, dray horses and carts were the primary means of transportation.

Furthermore, the cold chain has been around for quite some time. In the 1840s, the very first shipments of cold goods were made. Shippers waited until the weather was cold outside before shipping their perishable items on ice. This would ensure that the items remained at a cold temperature throughout the shipping process.

The technology behind the cold chain began to advance in the 1910s when cold goods began to be transported on ice in trucks. In 1925, when the refrigerated truck was first introduced, the precursor to the modern reefer trucks we see on the road today was put into service. (1) Since then, reefer trucks and containers have been essential to operating the cold chain and chain Drayage.

While we have discussed reefer containers and the large rectangle containers, we shouldn’t leave out the tanks that can be used during drayage shipping as well.

The term “intermodal tank” refers to a cylindrical container that is either 20 or 40 feet in length. It can hold liquid goods such as solvents, beverages, alcoholic beverages, fruit juices, and other chemicals.

Commonly known as ISO tanks, these shipping containers can be used both domestically (that is, between cities in the United States) and internationally (between cities in other countries). They travel on ships in the same manner as intermodal containers do.

IOS tanks also can be transferred between ships, trains, and trucks without the need for the cargo to be unloaded or reloaded during the drayage process. They are loaded onto well cars in preparation for their journey by rail.

When they are transported by truck, they are loaded onto a chassis for transportation. Depending on the commodity being transported, ISO tanks can be stacked on top of one another for the purpose of more efficient storage. Furthermore, they can be stacked one on the other when transported by rail.

Containers used for international shipping are typically either 20 or 40 feet long. These containers are utilized for intermodal shipping on an international and overseas scale. The products remain in the same container throughout the entirety of the journey, despite being moved between different modes of transportation such as cargo ships, trucks, and trains.

The length of a domestic container is typically 53 feet, and it can be either refrigerated or dry. Domestic containers are utilized for intermodal transport within the United States. Although shipments that travel in domestic containers are destined for inland (i.e., “domestic”) destinations, the products that travel in them may still arrive from overseas. This is because domestic containers only travel within the United States. In this scenario, products are transported to a port in international containers that are either 20 or 40 feet in length on cargo ships. After that, they are moved into domestic containers with a length of 53 feet at a cross-dock facility, a transload facility, or a distribution center. Products are then transported to their final destination further inland from there.

At PM Logistics Services, we are committed to providing you with the capacity and power to move your international freight to or from one of the nation’s many ports. With our nationwide reach, we ensure that your container drayage and transportation needs are met with dependability, timeliness, and professionalism.

Contact our team of professional intermodal drayage brokers today to find out how we can save you time and money on all your container drayage services in Charleston. We are here to help you find container drayage companies in South Carolina and provide you with the best service available.

Heavy hauling plays a crucial role in the logistics industry, ensuring the transportation of oversized and overweight cargo to various destinations. From construction machinery to

Freight shipping plays a critical role in supply chain management. It ensures the timely and efficient movement of goods from one location to another. However,

In today’s global economy, efficient freight logistics plays a crucial role in ensuring the smooth movement of goods and materials. As businesses strive for cost-effective

In today’s fast-paced world, efficient shipping is crucial for businesses to thrive. PM Logistics Services understands the importance of streamlined transportation solutions, and one such

Welcome to PM Logistics Services’ comprehensive guide to drayage services in Charleston and Greer, SC. In this article, we will delve into the significance of

In today’s fast-paced business environment, having visibility into the supply chain from producer to consumer is essential. This allows for maximum efficiency and reduces the